IMPACT

ETHICS BEFORE PROFITS

ECO-STYLIST

We achieved certified status with eco-stylist - an ethical fashion platform whose mission is to accelerate the world's transition to sustainable clothing by cultivating a community of brands you can trust.

We hit the benchmark in February 2025 in three key areas: transparency, fair labour and sustainability practices.

GIVING BACK

IMPACT

It's not all about having organic cotton and an ethical supply chain. That drives us for sure. But what REALLY drives us is being able to give back to worthy causes and make a real impact.

We're legally compliant to raise donations through Work For Good. Transparency is king. So we don't do ambiguous donations from net profits which can literally be anything (or nothing).

Instead, we give a transparent 2% of every sale to designated causes. You know exactly how much we'll donate on the cart page. We keep things fresh by changing the cause regularly.

1st January - 31st March, 2026

CURRENT IMPACT CAMPAIGN

We’re proud to support FoodCycle: a UK-registered charity whose vision is to make food poverty, loneliness and food waste a thing of the past for every community.

With community dining, week in, week out, they feed the hungry and give company to the lonely in their communities; providing delicious meals and great conversation, and using food which would otherwise go to waste.

We're donating 2% of every sale to FoodCycle in a 3-month campaign ending on March 31st, 2026. We hope to raise at least £1,200 which should mean a nice little feast (or feasts) at a couple of their community sites.

GIVING BACK

CAMPAIGN ARCHIVE

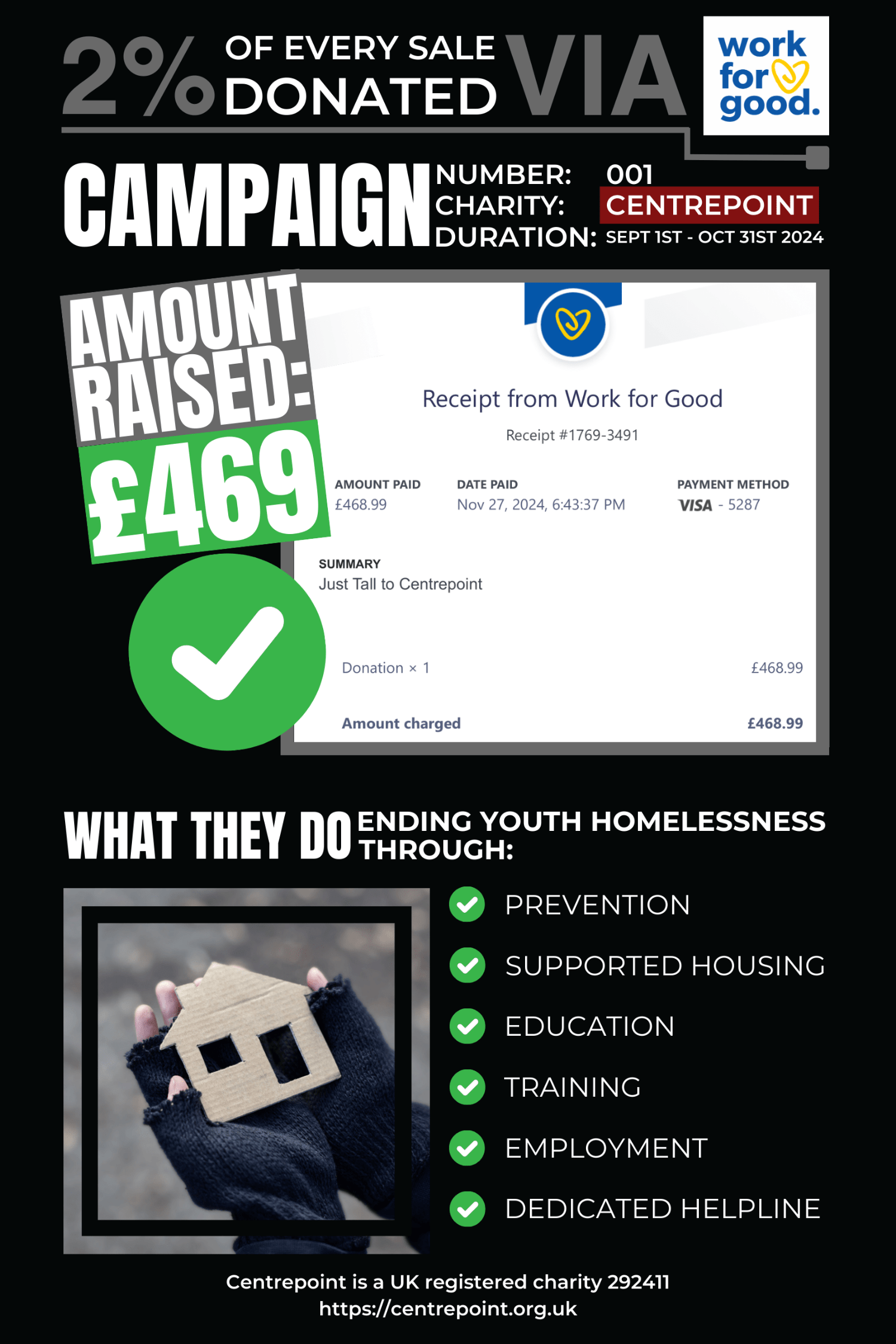

CENTREPOINT

Our first campaign was for Centrepoint. They're a UK registered charity whose mission is to end youth homelessness through prevention, supported housing, education, training & employment.

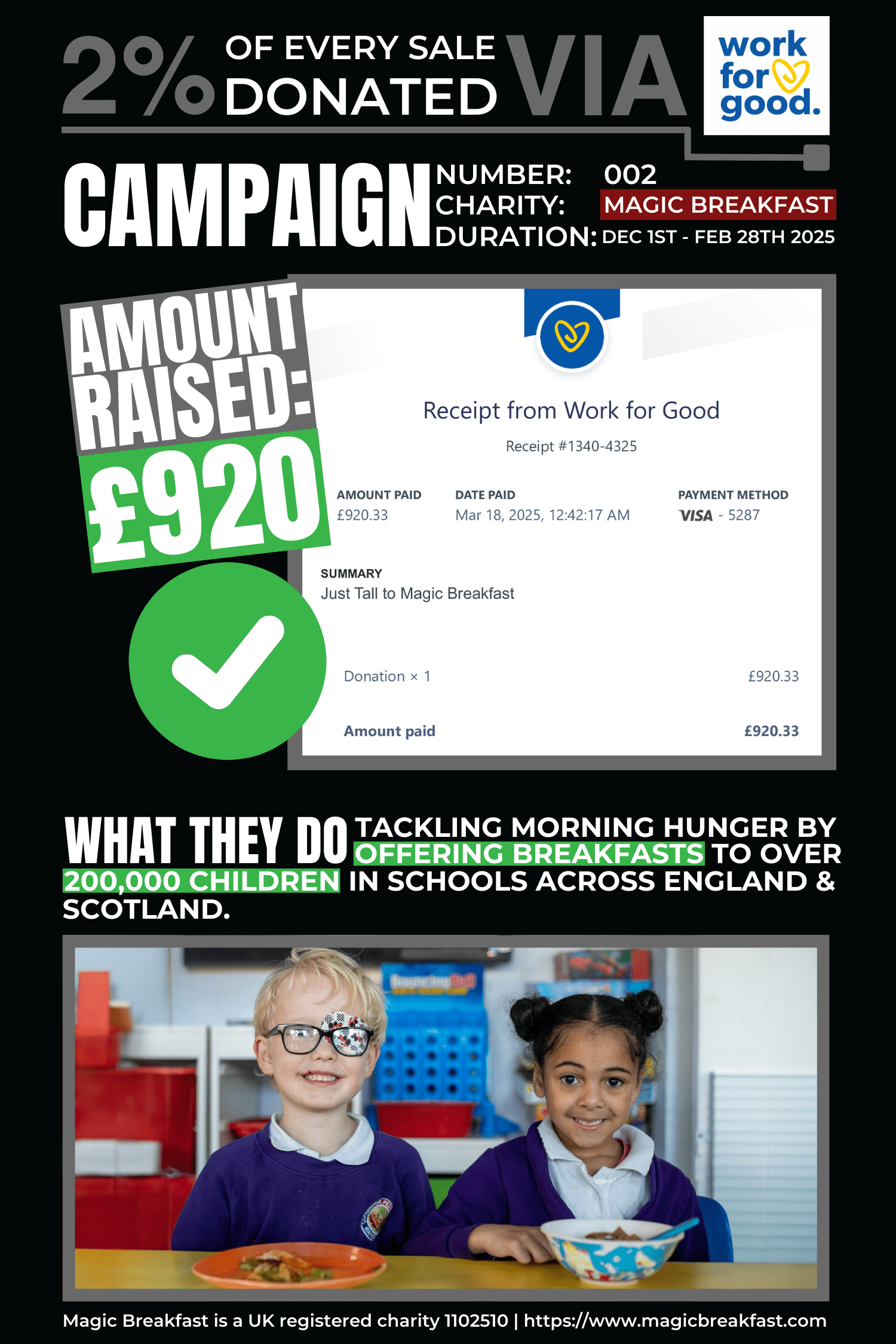

MAGIC BREAKFAST

Our second campaign was for Magic Breakfast.Their mission is tackling morning hunger by offering breakfasts to over 200,000 under privileged children in schools across England and Scotland.

MEDICAL AID FOR PALESTINIANS

Our third campaign was for Medical Aid for Palestinians. They're a UK-registered charity providing life-saving healthcare in Gaza and the West Bank.

ETHICS BEFORE PROFItS

ETHICAL & QUALITY MANUFACTURING

Sweatshops are everywhere. Not just in Asia, but even in the USA! Google 'California sweatshops' and you'll see what we mean. You'll realize that 'Made in the USA' doesn't always necessitate it's ethically made.

Unfair wages and excessive hours are all part and parcel of sweatshops. That's why many fast fashion brands can sell at ultra-low prices. They can easily sell a t-shirt for a few dollars when their garment workers are paid next to nothing. The quality is usually ridiculously poor too.

Worker exploitation and poor-quality throwaway fashion are our red lines. The factories we source from are all GOTS (Global Organic Textile Standard) certfied. That means a certifying body regularly inspects these factories to check their workers are paid livable wages, paid overtime and work in safe conditions. It also means they avoid rotten stuff like forced and child labor.

Because our workers are paid decently, we actually pay our suppliers more for a single t-shirt than what fast fashion brands sell for. But that's a small price to pay for an ethical supply chain and superior quality slow fashion that lasts wash after wash.

TRANSPARENCY

OUR GARMENT MANUFACTURER

We don't do greenwashing. That's when a business misleads customers by falsely claiming to be ethical and friendly to the environment. Businesses wanting to jump onto the environmental bandwagon should prove how they're making a difference. That includes choosing a final production facility that ticks as many ethical boxes as possible.

We currently have 100% traceability of our final production and produce all of our clothes in one factory, Sree Balaji Intl. Dealing with one factory makes auditing and assessment much easier. We'll make our first yearly visit in July 2025 to assess how well they're doing.

FACTORY DATA

✅ Registrations: SEDEX, BSCI

✅ Certifications: GOTS. See certificate.

OEKO TEX. Renewing March 2025

✅ Number of workers: 106

✅ No child labor, no forced labor

✅ Lowest paid worker: 30% above legal minimum wage in Tamil Nadu

✅ Working week: 6 days, 48 hours per week

✅ Overtime: Paid at 2x

✅ Benefits: 50% discounted meals, free transportation to and from the factory

TRANSPARENCY

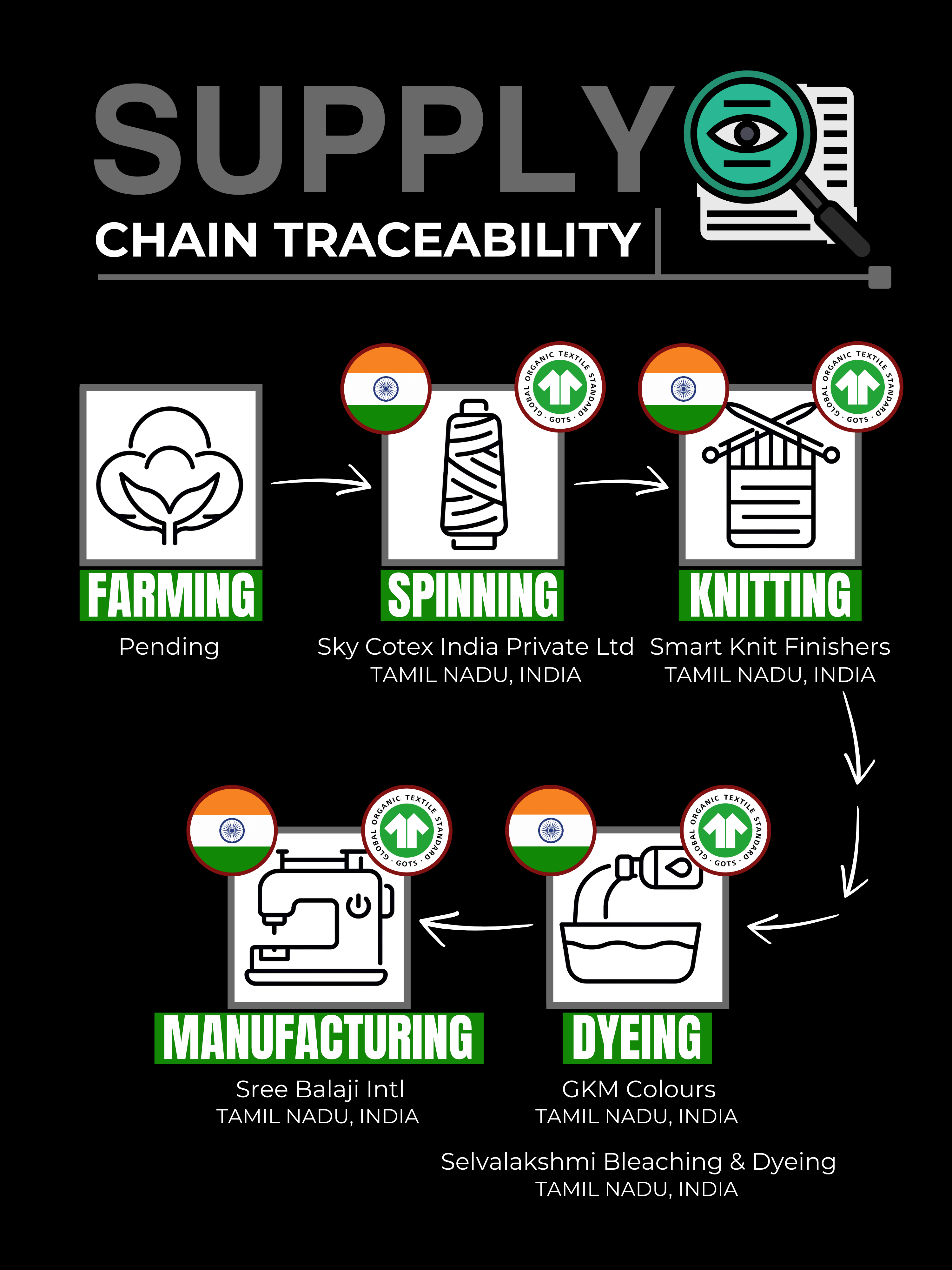

OUR SUPPLY CHAIN

It can be risky for micro businesses like us to disclose their supply chain. Our much bigger competitors could walk all over us with this knowledge. But the benefit of you knowing exactly who we deal with is a no-brainer. It helps builds trust that we do actually care about ethics & sustainability.

Our supply chain is simple and we currently have 80% traceability of our entire supply chain. We’re working on full 100% traceability and plan on hitting that target by 2026.

FACILITIES

Spinning facility (Tier 3)

Sky Cotex India Private Ltd

✅ Certifications: GOTS. See certificate.

Knitting facility (Tier 2)

Smart Knit Finishers

✅ Certifications: GOTS. See certificate.

Dyeing facilities (Tier 2)

GKM Colours

✅ Certifications: GOTS. See certificate.

Selvalakshimi Bleaching & Dyeing

✅ Certifications: GOTS. See certificate.

Manufacturing facility (Tier 1)

Sree Balaji Intl

✅ Certifications:

GOTS. See certificate.

OEKO TEX. See certificate.

TRANSPARENCY

OUR POLYMAILER MANUFACTURER

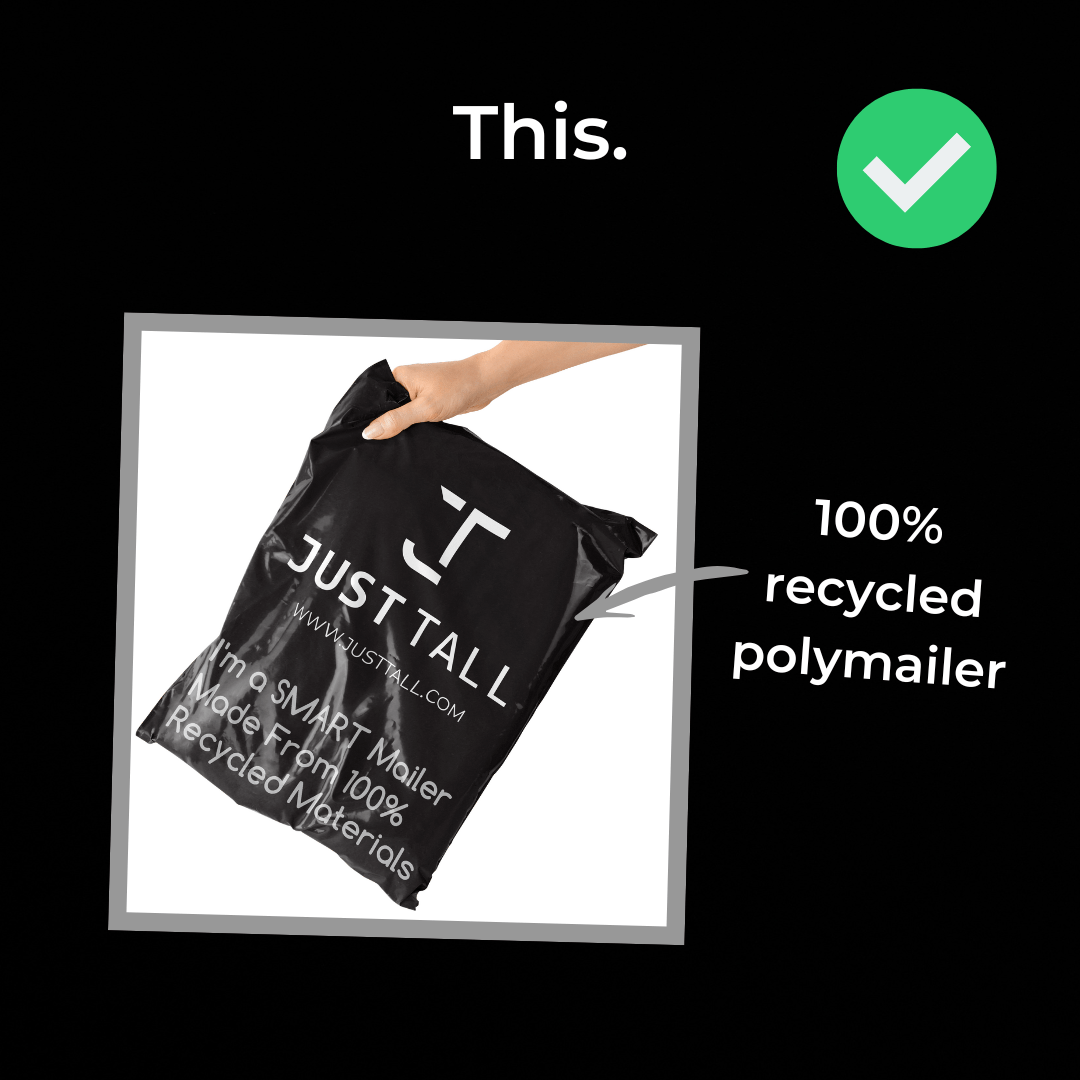

Polybags Ltd have made our external polymailers since we launched in 2022. They're made of Ravalene®, a 100% recycled natural LDPE compound from post industrial sources. Check out the data sheet here.

They're also certified in ISO9001:2015. This is a standard that helps companies keep their quality in check, making sure they meet customer needs and keep getting better. It’s all about good leadership, handling risks, and improving things over time to keep customers happy.

TRANSPARENCY

OUR USA 3PL (3RD PARTY LOGISTICS) PARTNER

Ecoship, a family run e-commerce fulfillment company, have handled our USA logistics since April 2022. They're hot on sustainability and fair labor practices. Their B-Corp certification is in progress too!

100% ORGANIC COTTON

SUSTAINABLE FABRICS

Standard, non sustainable fabrics harm people and ruin the planet. Polyester is a man made fabric. The manufacturing process releases chemical toxins which pollute the air and harm factory workers.

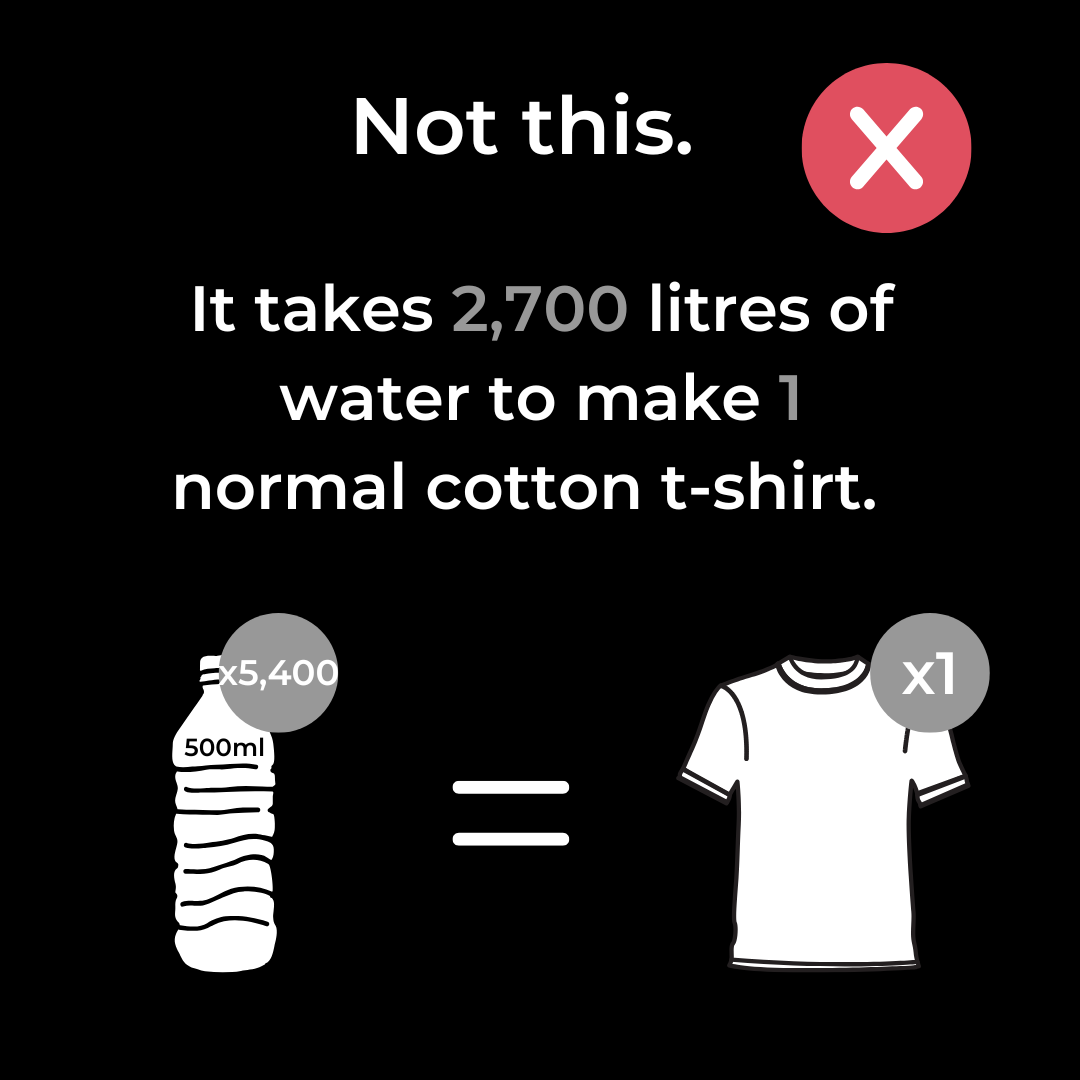

Standard cotton is another unsustainable fabric. Growing cotton needs huge amounts of water. It can take up to 5,400 500ml bottles of water to make just one cotton t-shirt. Growing standard cotton also needs chemical fertilizers which harm the soil, surrounding vegetation and the wildlife depending on it.

We only use sustainable fabrics such as GOTS certified 100% organic cotton. Growing organic cotton consumes up to 90% less water during production and uses only natural fertilizers.

LESS IS MORE

LIMITED QUANTITIES

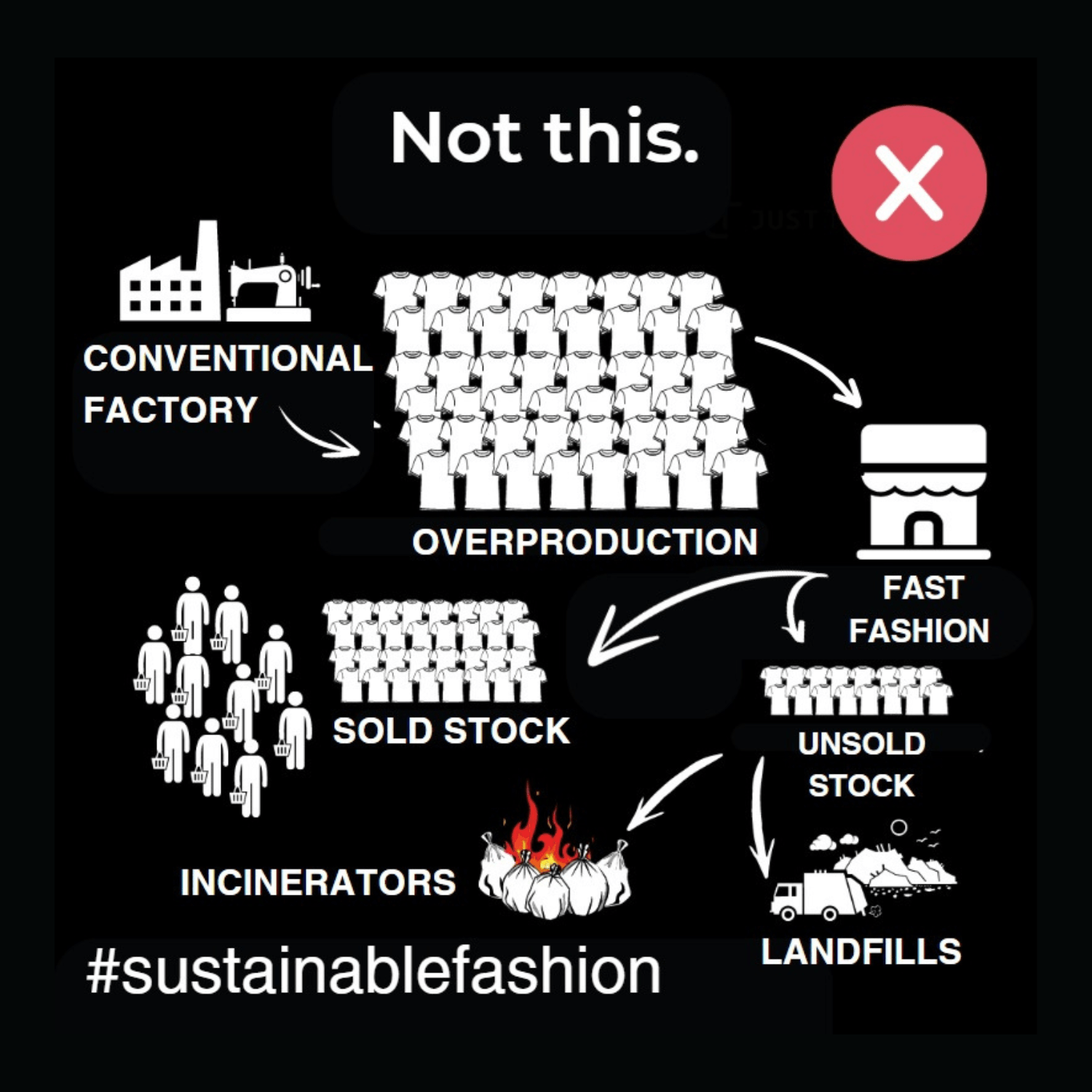

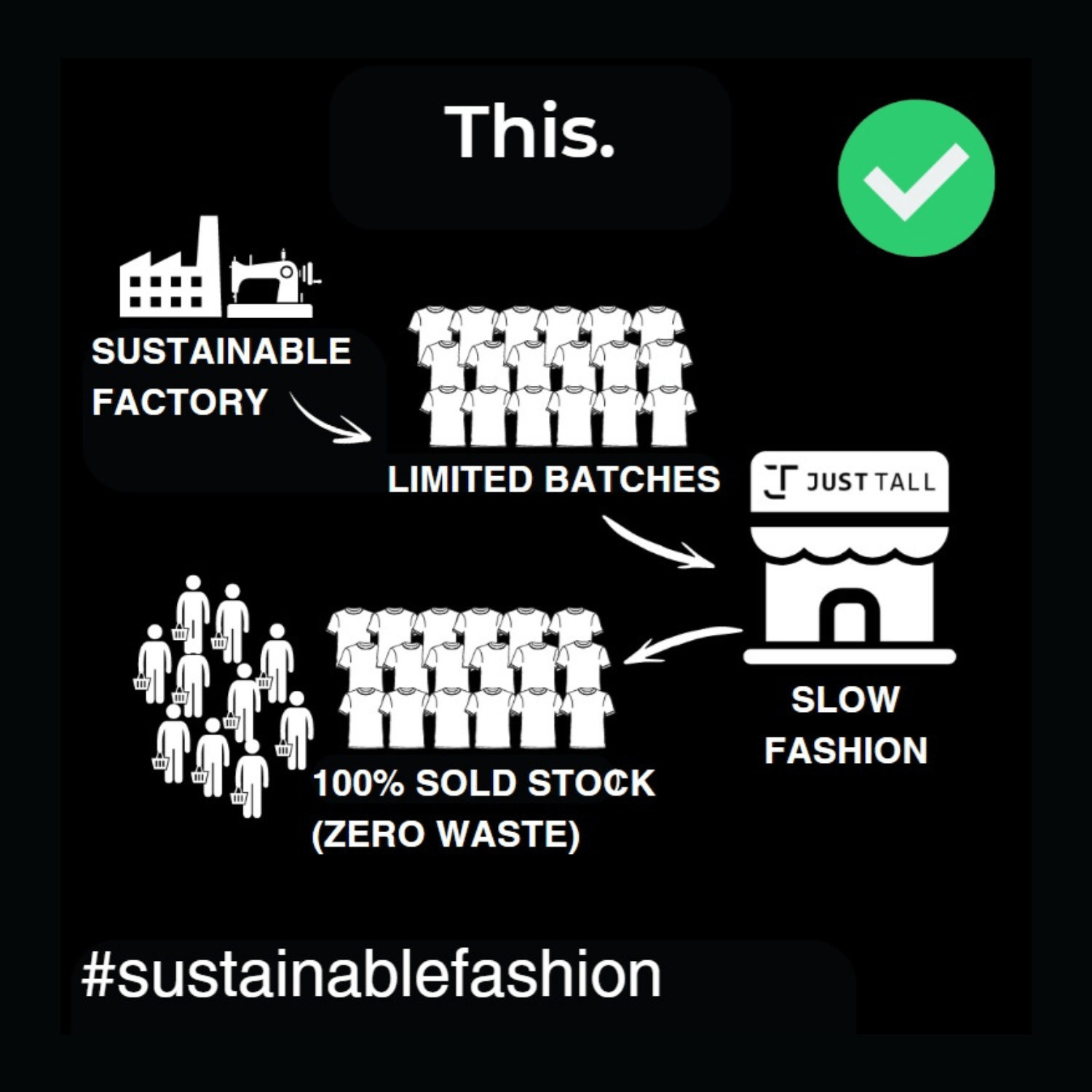

Fast fashion brands have deep pockets. They're so deep that they'll overbuy inventory, seduced by deep factory discounts for buying big quantities. A percentage of that order won't get sold. This unsold stock (deadstock) can end up in landfills or in incinerators. What a waste.

We hate waste, especially apparel waste. For us, less is always more. We only order by market demand, even if it means we have to pay more for limited quantities. This helps us to sell 100% of our inventory with zero waste, taking pressure off the supply chain.

POLYMAILERS USED BEFORE

RECYCLED PACKAGING

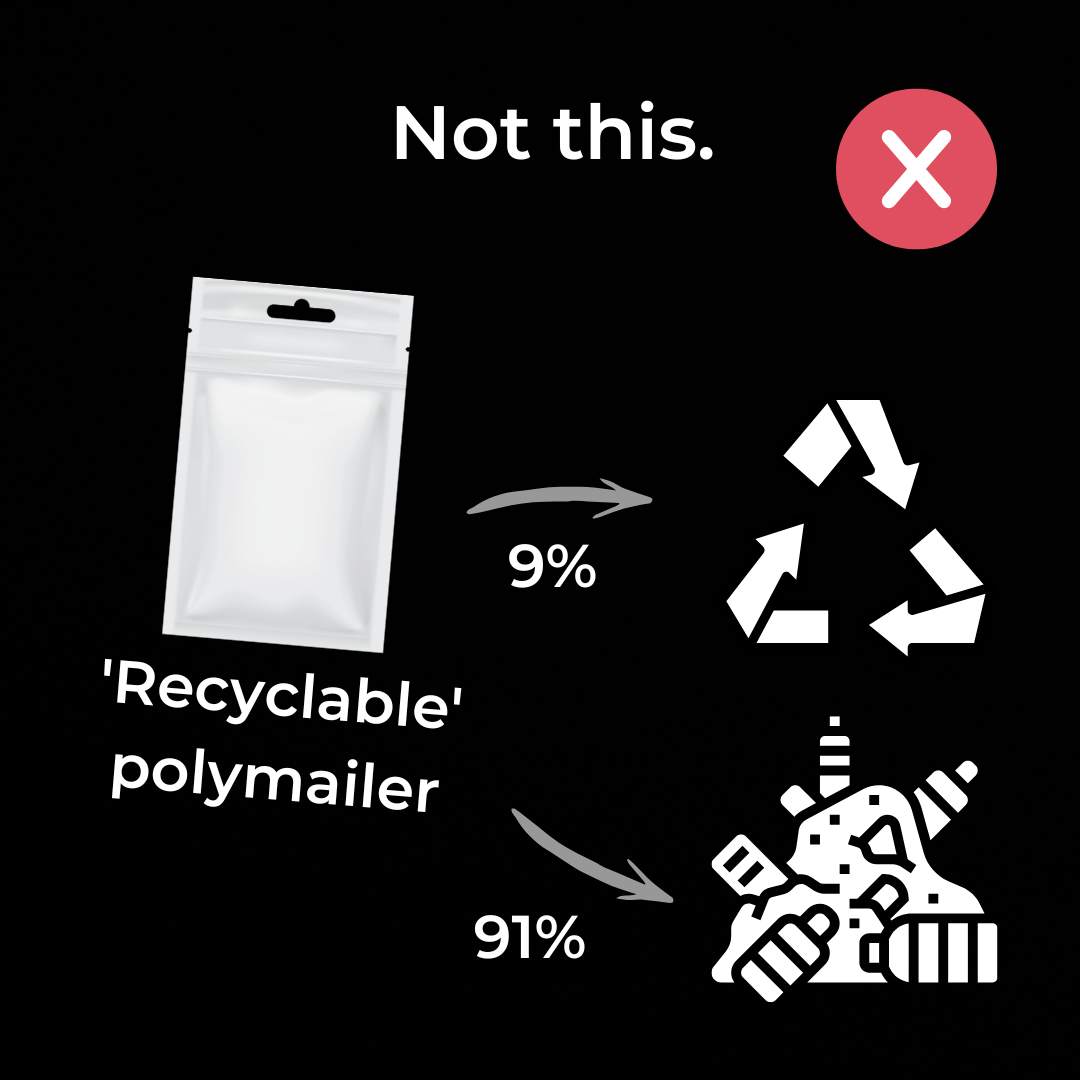

We use way too much plastic - up to 5 trillion plastic bags worldwide every year. That is only 5,000,000,000,000! Around 10% of all plastic ends up in the world's oceans. And only 9% of all recyclable plastic actually gets recycled. The rest is only used once and can end up at landfills. Horrific.

We're doing our part in reducing plastic use. All our (cool) black poly mailers are made from 100% post-recycled plastic. That means the plastic in them had already been used somewhere else. And you can recycle our poly mailers again. After ripping out your lovely tall menswear in delight, of course.